Your Essential Guide: Choosing the best Drain Jetter Spec and why hose size is key

What spec PowerPlate Drain Jetter should I purchase?

This is a question we get asked all of the time.

9 times out of 10 the answer usually is… it all depends on your requirements, and budget.

The old days of just getting a 4000PSI @ 12GPM and expecting it to do every job have gone, we now live in a far more technically minded and busy world, where efficiency is key and time is money. Theres more drain blockages now than ever, and the more you can achieve in a day impacts your pocket massively!

HCM have a specialist team on hand to ensure we get you the right equipment, within your budget!

Lets delve into just some of what goes into the deciding factors of what spec to purchase. Be mindful, it can be quite a tricky read if you're a complete beginner and not familiar with the technicalities of drain jetting, If you feel the need please give us a call on 01928 568 066 and we can discuss in more depth with you over the phone.

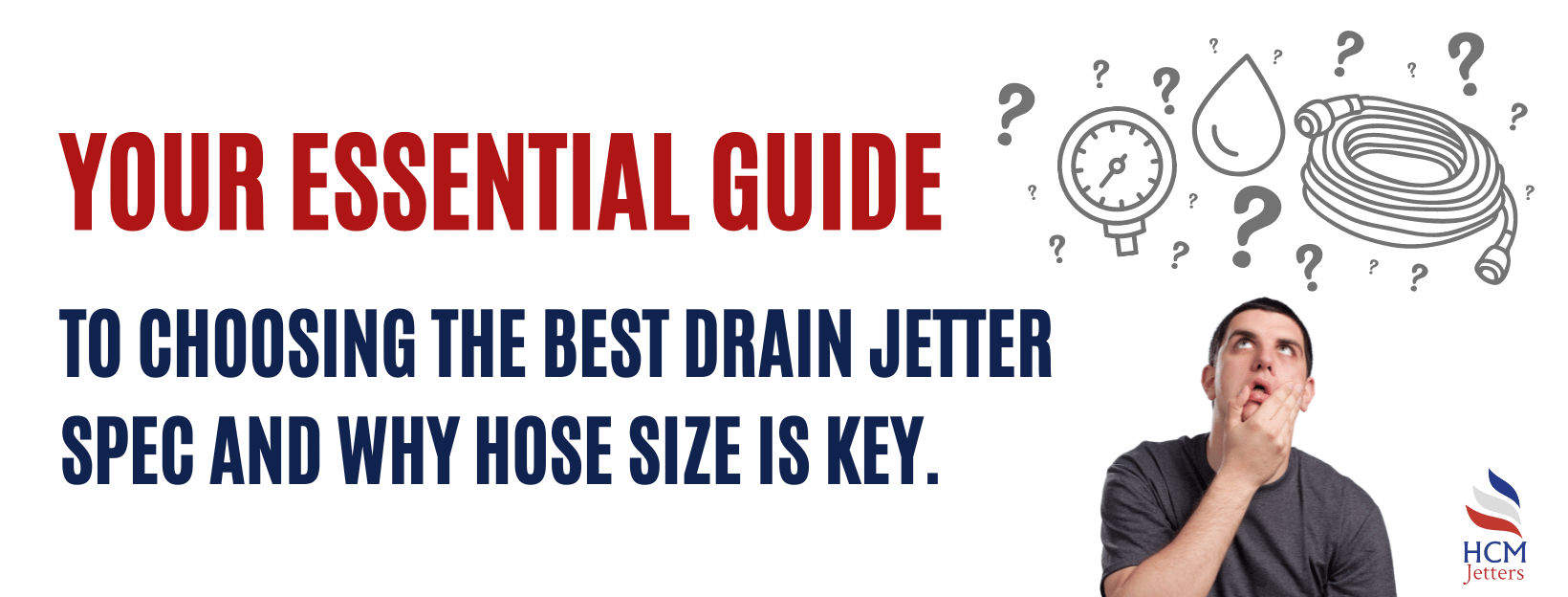

Here at HCM we have a standard hose sizing that we use across the board on our systems, take a good look at this, as it all plays a key factor in the decision of your jetting unit spec, the ability to control how easy it is to achieve the removal of the blockage, can all lie in the hose size.

However, there is a knock on effect as each hose has a maximum flow rate before it creates the fateful back pressure, and ultimately damage the pump.

For this reason we work off three main sizes as follows:

Machines up to 15LPM (Litres per minute) we will use 1/4" BSP hose (Smaller + portables)

For machines from 15 - 35LPM we will use 3/8" hose.

For machines from 35 - 73LPM we will use 1/2" hose.

So going back to the question of spec choice required, we understand that the hose sizes differ, However on what hose to choose will largely be based on the primary focus of works that will be undertaken. Too big and you will spend most your water trying to get around the first bend, too small and you will skip over the silt, the type of work undertaken will play a pivotal role.

Lets take a look at some examples

A standard domestic unblock

let's assume that the standard house unblock is going to be your primary focus of work. You’re going to be faced with mainly 4” drains, occasionally 6”, and you want the right hose that can navigate all the bends and restrictions that come your way. For this you would benefit from a 3/8” hose. As you read above the maximum flow rate a 3/8” hose will take is 35 litres per minute (LPM), So assuming most of your work will be doing domestic/ house blockages we would recommend heading as close to 35LPM as possible. For that and for heavy use usually we recommend no less than 30LPM at a comfortable pressure of 3000 Pounds Per Square Inch (PSI), that being said it doesn't necessarily mean you are restricted to only these jobs, you will in most circumstances be comfortable clearing a blockage on a domestic job with quarter inch or even half inch, we are simply talking about maximising efficiency.

Larger straight runs desilting jobs/ Main lines

The same analogy can be said for bigger 6” to 9” longer run drains, whereas in the previous paragraph we recommended the 3/8” hose up to 35LPM, in this circumstance we would definitely recommend a ½” hose powered unit and a higher volume of water. The larger the water volume the better flushing power, so for desilting works getting close to the 70LPM specs would really benefit you.

Water usage

There is another factor that can be part of your decision process and this is your access to water whilst working and what size tank unit you choose.

For example, our power plate series consists of three main system builds, 350 Litre [350 series], 500 Litre [500 series], and 800 Litre which is if you haven't guessed already is our [800 series] unit.

The litres corresponds with the on board water tank supply of the jetting unit so if you have one of our 350 series jetting units, it would be irresponsible of us to suggest kitting this out with a 73 litre per minute PowerPlate! As you would spend most of your time refilling and sat waiting.

Budget your way to success

It's important not to overlook that another major factor is simply budget dependent, obviously the more you pay will provide you with more spec, additional extras, and ultimately increased performance.

HCM have developed an amazing solution, and all power plate systems have the ability to grow with your business, the range of additional extras such as wireless control, electric hose reel, and so on can all be added at a later date if required, this is a very unique feature that we are really proud of at HCM.

But even better still, our proudest achievement of the power plate series lies what in its ability to completely change the spec at a later date. Without needing to replace the whole system, this is completely unique in the drain jetting world and we are the one to offer this. This gives you full peace of mind should your requirements change overtime (and it can) You can radically change the spec by just changing the power plate.

This system also works with any maintenance and servicing, No need to leave your unit / van with us. We can quickly swap out your PowerPlate and replace with one of our Loans. This gets you back out on the road with minimal downtime whilst we carry out the works.

Smaller PowerPlates and Portable units

We've learned that the 3/8” inch hose is probably the best option for 4” domestic drain works (with a little 6” on the side), and for the bigger runs the ½” inch hose prevails, so where does the ¼ “ hose come into this, and what benefit does that bring?

Well it's actually an interesting concept and it was HCM Jetters that brought a ¼” hose jetting unit into the market…

If you were to travel around the country, open the doors and look inside the back of most drain jetting vans (don’t you’d probably get arrested) but you would be pushed to find any van set up that doesn't contain 10 metres or so of mini hose, the mini hose really comes into its own more specifically on gully jobs, or really tightly restricted jobs.

And for 90% of domestic jobs the quarter inch hose can also be used, it's quite common for drain operatives to equip the mini hose to the end of their standard hose to do some works on gullies, who only to find they prefer it. It tackles the blockages fine, with the key benefit of using less water,

the reason for the last statement of ‘using less water’ is all down to back pressure being produced. Although using a little bit of mini hose at the end of the machine won't really do much harm over time, you're restricted to a maximum length of around 10 metres before causing damage to the pump.

If only there was a solution..

Here at HCM we developed an incredibly popular and successful solution to this problem, we designed a system that can cope with longer lengths of mini hose by reducing the overall flow rate of the unit. These systems can house up to 60M+ of mini hose and with them only needing smaller engines they are incredibly budget friendly and make an ideal unit for quicker unblocks. These are available as a portable option in our Viper Series, or our 14HP PowerPlates. Obviously the larger units will provide the extra flow rate to increase the speed of a desilt or thorough cleanse, but make no mistake these little units pack a mighty punch!

What about pressure?

You may have noticed we have barely brushed talking about pressure, and that’s for good reason. Pressure, although it is a slightly important factor, many seem to value pressure way too highly when it comes to picking a Drain Jetter.

Although yes, the pressure will provide a deeper cut, you will quickly realise that it’s actually the flow rate that provides you with most of the benefits. If you give someone two machines with no pressure gauge on either and ask what machine is the most powerful, or what machine has the most pressure, 95% of the time they will choose the one with the higher flow rate.

You need at least ideally 2000PSI however most of our units are a minimum of 3000PSI. It's all about finding the right balance between pressure and flow rate, the HCM specialist team spend every day testing and engineering specs to find the perfect balance for customers just like you.

In Summary

We strongly recommend speaking to us first before making any purchase, and that's because we just want to make sure you get the right jetting unit. If we do our job properly, we know that it will become a business opportunity for us both, you will continue to support us and you can maximise your workload. If you succeed and grow then we do too, so it's in our interest to make sure you get the right machine. We know our stuff, many of us have worked in the industry ourselves some for 40+ years before coming to HCM so we can also provide valuable knowledge before and even after getting your Jetter.

We understand you can have your mind already set on a Jetter Spec and it's completely your decision on your final choice of unit so don’t feel pressured (excuse the pun) but we will always endeavour to give any friendly advice where we can. (Plus we’re a chatty bunch) :)

Call us on 01928 568066

Visit us in store

or e-mail sales@hcmjetters.co.uk to speak to the team.