Top 5 Common Drainage Problems and How to Solve Them Efficiently

As professionals in the drainage industry, you're no stranger to the challenges that arise in keeping systems running smoothly. From unexpected blockages to dealing with storm-induced flooding, each job presents its own set of obstacles. At HCM Jetters, we understand the importance of having the right tools at your disposal, which is why we're here to guide you through the most common drainage problems and how to tackle them effectively.

1. Blockages Due to Grease, Fats, and Oils

One of the most common causes of drainage issues is the accumulation of grease, fats, and oils (FOG). These substances, often found in wastewater from kitchens and food-related businesses, can enter the drainage system in a liquid state. However, as they cool, they solidify and cling to the inner walls of pipes, creating stubborn blockages. Over time, this build-up narrows the pipes, restricts water flow, and traps additional debris, such as food particles.

.png)

The presence of FOG in pipes can lead to significant operational disruptions, including increased pressure within the system, leaks, or even pipe bursts. In colder weather, these blockages can form more quickly as FOG solidifies faster. For businesses, particularly those in the food industry, this can result in costly downtime and health hazards from potential wastewater backups which is where you come in.

Solution:

Our High Pressure Drain Jetters are perfect for clearing these types of blockages. They deliver powerful water jets that cut through and wash away stubborn build-ups, restoring the flow quickly and efficiently. Providing your customers in this line of business regular maintenance with can also help prevent future blockages, ensuring smooth operations and costly repairs further down the line.

But which nozzle jet do I use? This is a question we get asked all the time. Each job is completely different, factors such as pipe diameter, pipe material, the size of the blockage, the cause of the blockage all contribute to different approaches. As a general rule we would suggest trying a standard jet, spinning nozzle, milling nozzle or forward root cutter but sometimes water alone can't get rid of stubborn solid deposits no matter the power of your machine or methods used. In this instance we would recommend the use of a mechanical drain cleaner.

2. Root Intrusions Causing Pipe Damage

Tree roots pose a serious threat to drainage systems, often turning into a complex and costly issue for professionals in the field. Roots naturally seek out moisture and nutrients, which makes underground pipes a prime target. The small, hair-like root structures can infiltrate tiny cracks or joints in the pipes, initially going unnoticed. Once inside, they grow rapidly, expanding and exerting pressure that can lead to severe structural damage.

As roots grow within the pipes, they can cause a variety of issues. The most immediate problem is the restriction of water flow, leading to blockages. Over time, the relentless growth of roots can cause the pipes to crack or break, increasing the problem and potentially leading to complete pipe failure. This damage not only disrupts the drainage system but can also create hazardous conditions if wastewater backs up and contaminates the surrounding area.

Solution:

For drainage engineers, addressing root intrusion requires both accurate diagnosis and effective remediation. The first step is often using advanced drain inspection cameras to locate the extent and exact location of the root invasion. These cameras provide clear visuals, allowing you to assess the severity of the situation and plan the appropriate intervention.

Once identified, removing the roots can be accomplished using specialized high-pressure jetting units equipped with root-cutting nozzles. These tools efficiently cut through the roots and clear the pipe, restoring normal flow. However, removing the roots is only part of the solution. It's also crucial to repair any damage and prevent future intrusions. This is where patch lining equipment comes into play, offering a non-invasive method to seal cracks and strengthen the pipe structure, preventing further root ingress.

Preventative measures, such as installing root barriers or using chemical root inhibitors, can also be considered for long-term protection. By taking a comprehensive approach to managing and mitigating root intrusion, drainage engineers can effectively protect infrastructure and maintain the efficiency of drainage systems. For more detailed information on the tools and techniques available, check out our selection of drain cameras, root cutters and patch lining products on our website or speak to a member of the team on 01928 568 066.

3. Pipe Corrosion and Leaks

Over time, pipes are prone to corrosion, a common issue particularly in older drainage systems or those frequently exposed to harsh chemicals. As you know, corrosion occurs when the pipe material reacts with substances in the water or soil, leading to gradual degradation. This process can cause the pipe walls to thin and weaken, eventually resulting in leaks or even complete pipe failure. For drainage engineers, addressing pipe corrosion is a critical aspect of maintaining system integrity and preventing environmental contamination.

Corroded pipes can lead to a host of problems. Leaks not only reduce the efficiency of the drainage system but can also cause damage to surrounding structures and the environment. For instance, water escaping from a corroded pipe can erode the surrounding soil, potentially undermining foundations and causing subsidence. Additionally, leaks can lead to significant amounts of waste water overflowing into surrounding areas resulting in bad smells and contamination. Identifying and addressing these issues early is crucial for preventing more severe problems down the line.

Solution:

The most effective solution involves a combination of advanced diagnostics and targeted repairs. Utilizing drain cameras and drain dyes can help locate leaks and assess the extent of corrosion without intrusive measures. Once identified, several techniques are available, depending on the severity of the damage.

For minor leaks and corrosion, applying a patch lining can offer a quick and cost-effective solution. This method seals the affected area, preventing further leakage and extending the life of the pipe. In cases where corrosion is extensive, pipe replacement might be necessary, particularly if the structural integrity is compromised.

Regular maintenance and monitoring are essential in preventing corrosion-related issues. Recommending annual inspections and advising clients on proper chemical disposal can help mitigate the risks. For more comprehensive solutions and to explore the range of products designed to address these issues, visit our patch lining and drain camera sections.

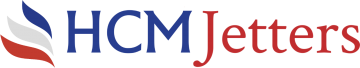

4. Flooding from Heavy Rain and Storms

Flooding poses a significant challenge to drainage systems, especially in areas prone to heavy rain and storms. For drainage engineers, managing the sudden influx of water is a critical task, as it can overwhelm both natural and man-made drainage systems. Flooding not only disrupts normal operations but can also cause extensive damage to properties and infrastructure.

Heavy rainfall can lead to surface water accumulation, particularly in areas with poor drainage. When the water cannot drain away quickly enough, it can lead to localized flooding, affecting homes, businesses, and public spaces. This issue is exacerbated in urban areas, where impermeable surfaces like concrete and asphalt prevent water from naturally soaking into the ground.

Solution:

Effective flood management requires a proactive approach, starting with a thorough assessment of the drainage system's capacity and condition. Regular maintenance, including clearing gutters, drains, and culverts of debris, is essential to ensure the system can handle sudden surges of water. Our range of high-pressure water jetting units are ideal for keeping these channels clear and functional.

In addition to maintenance, installing stormwater management solutions can help mitigate flooding risks. These include retention basins, permeable pavements, and rain gardens, which help absorb and manage excess water. For properties at high risk of flooding, recommending the installation of flood barriers or backflow prevention devices can provide an additional layer of protection.

In the aftermath of flooding, rapid response is crucial to minimize damage. Our range of pumps and extraction equipment can aid in quickly removing floodwaters, preventing prolonged exposure to moisture that can cause further damage. Here’s a closer look at some of the key tools we offer to help you manage flood situations effectively:

Venturi Pumps

Venturi pumps or also known as Mud Suckers are highly efficient tools that operate without moving parts, making them reliable and easy to maintain. These pumps work by utilizing the Venturi effect, where water flow through a constricted section of pipe increases velocity and decreases pressure, creating a suction effect that can draw in additional fluid. Our Venturi pumps are designed to attach to our high-pressure drain jetters, harnessing the power of the pressure and water flow of these jetters to create the Venturi effect. This setup is particularly useful in flood situations where electricity is unavailable or impractical. The simplicity and robustness of Venturi pumps make them an excellent choice for quickly removing standing water.

Loncin 1" Water Pump

The Loncin 1" Water Pump is a compact yet powerful solution for water extraction. Equipped with a robust engine, this pump can handle substantial volumes of water, making it perfect for rapid flood response. Its portability allows it to be deployed quickly to affected areas, and the 1" inlet and outlet ensure efficient water removal. The Loncin pump’s durability and reliability make it a trusted tool for drainage engineers facing flooding emergencies.

Milwaukee M12 Stick Transfer Pump

The Milwaukee M12 Stick Transfer Pump is a versatile and user-friendly tool designed for efficient water transfer. Powered by Milwaukee's M12 battery system, this pump offers cordless convenience, making it easy to use in various locations without the need for a power outlet. Its compact design allows for easy handling and storage, while its powerful motor can pump up to 9 gallons per minute. This makes the M12 Stick Transfer Pump ideal for quickly addressing small to moderate flooding issues, ensuring that areas are dried out swiftly to prevent further damage.

For more information on flood prevention and recovery tools, explore our drain jetters and water extraction tools on our website. At ShopHCM, we provide the equipment you need to respond to emergencies effectively and keep your operations running smoothly.

5. Structural Damage to Pipes

Structural damage to pipes is a serious concern that can result from a variety of factors, including ground movement, heavy traffic overhead, or simple wear and tear over time. For drainage engineers, identifying and repairing structural damage is a critical task, as compromised pipes can lead to leaks, blockages, and even complete system failure.

Ground movement, whether from natural causes or human activities such as construction, can displace pipes, leading to cracks or breaks. Similarly, heavy vehicles passing over buried pipes can cause them to shift or compress, compromising their structural integrity. Over time, even pipes that are properly installed and maintained can deteriorate, particularly if they are exposed to corrosive substances.

Solution:

Addressing structural damage requires a comprehensive assessment to determine the extent and cause of the damage. This often involves using drain cameras to inspect the interior of the pipes and identify cracks, breaks, or misalignments. Based on the findings, the appropriate repair method can be selected.

In many cases, trenchless repair techniques such as patch lining or full pipe lining can be used to repair damaged pipes without the need for extensive excavation. These methods not only save time and reduce costs but also minimize disruption to the surrounding area. In cases where the damage is extensive or the pipe material is significantly degraded, full replacement may be necessary.

Prevention is also a key aspect of managing structural damage. This includes regular inspections, proper installation techniques, and using high-quality materials that can withstand environmental stresses. For more detailed information on the products and methods available for repairing and preventing structural damage, visit our patch lining, lining and drain camera sections.