Troubleshooting Low Pressure: Keep Your Jetter Flowing Strong

At HCM Jetters, we know that nothing grinds your gears more than a jetter that’s just not pulling its weight. Low pressure on the job can turn an easy day into a frustrating slog. But before you shut the van doors and call it quits, let’s take a moment to walk through some troubleshooting steps that might just save your day.

Understanding what’s happening under the pump can make all the difference. So, grab a cup of coffee, and let’s dive into the nuts and bolts of why your jetter might be experiencing low pressure—and how to fix it.

The Basics: Why Pressure Matters and How It’s Made

First things first: let’s clear up a common misconception. Your pump doesn’t actually “create” pressure.

Nope! Pressure is the result of forcing water through a restriction—think of your jetter nozzle as the hero in this story. The pump’s job is to keep the water flowing at a consistent rate, measured in gallons per minute (GPM) or Litres per minute (LPM). If you’ve got the right nozzle but still see low pressure, the root cause is likely a reduction in GPM / LPM reaching the nozzle.

So, what’s the takeaway? If your pressure is low, it’s not about the pump being lazy—it’s about the water not getting where it needs to go with enough oomph.

Let’s figure out why...

Start Simple: Quick Checks Before You Panic

Before you start dismantling your jetter and daydreaming about new equipment, let’s start with some simple checks. Sometimes, the problem is as straightforward as a missed step in your routine maintenance:

Check your Oil:

Just like you wouldn’t drive your van without oil, your jetter needs lubrication to keep all those moving parts running smoothly. Low oil levels can cause all sorts of issues, including low pressure on some pumps.

Clean your Water Filter:

If it’s clogged up with debris, the water flow is going to suffer. A quick clean might be all you need to get things back on track. Also check there are no tears in the wire mesh of the filter. Tears can lead to debris passing through rendering the filter useless. Once this happens the dirt can quickly make its way to your pump and cause even further damage.

Check your Water and Fuel Levels:

If there’s not enough water in the tank, your jetter simply can’t perform. Make sure you’ve got plenty of water before you start troubleshooting other potential problems.

Inadequate fuel levels especially if your van is parked on a sloped or uneven surface can cause the engine to starve resulting in less power to the pump. Ensure sufficient levels to rule out your fuel to be the cause of low pressure.

If you are unsure where to locate your oil or water filter get in touch and we will be happy to help

Nozzle Know-How: Size Matters

Your nozzle is the final gatekeeper of pressure. A worn-out or incorrectly sized nozzle can wreak havoc on your jetter’s performance:

-

Inspect the Nozzle: Make sure it’s properly sized and not worn down. Less restriction means less pressure. If the nozzle’s seen better days, it’s time for a replacement.

-

Test with Multiple Nozzles: Start with the nozzles that came with your jetter—they’re designed to work best with your specific setup. Avoid spinning or specialty nozzles during your initial troubleshooting, as these can require significantly more flow and pressure to function correctly.

Pro Tip: If you are not sure which nozzle is right for your jetter, get in touch with us, and we’ll guide you in the right direction.

Hoses and Fittings: The Unsung Heroes

Don’t overlook your hoses and fittings—they could be the culprits behind your low-pressure woes:

-

Inspect for Leaks: A tiny leak can lead to a big drop in pressure. Check all hose connections and fittings for signs of wear or damage.

-

Check for Kinks or Blockages: Even a small kink in the hose can reduce water flow. Make sure your hoses are in good shape and free of any blockages.

Regular inspection and maintenance of your hoses and fittings can save you from bigger headaches down the line.

Fine-Tuning: Adjustments That Make a Difference

Now that the basics are out of the way, let’s talk about some of the more in depth adjustments that could be the culprit:

-

Engine Speed: Make sure your engine is running at full throttle. A drop in RPMs can lead to a drop in GPM, which means lower pressure. Double-check that your throttle is fully engaged and the engine is roaring at full power.

-

Unloader Valve Setting: Your unloader valve plays a crucial role in managing pressure. If it’s not adjusted correctly, you might be losing pressure before the water even hits the nozzle. Adjusting the unloader to increase pressure can solve the problem but here’s a word of caution—if there is no change in the pressure gauge, stop immediately. Over-tightening the unloader can lead to a dangerous situation if a restriction is introduced (like closing a valve). Even if your jetter can’t hit max pressure with a nozzle, it can still spike to the unloader’s max setting if there’s enough restriction.

This adjustment should NOT be done without the supervision of our engineers either in person or over the phone to access wether or not it is indeed the cause and to properly instruct how to perform the action. If you feel your unloader could be the culprit please just give us a call before attempting making any adjustments so we can ensure your safety and your jetter remains intact.

The Visual Check: Is the Pump Really to Blame?

Low pressure doesn’t always mean the pump is at fault. Before you start unscrewing anything, do a quick visual check of your system while it’s running:

Look at the Tank: Specifically, look into the tank near the return hose while the unit is operating. If you see water returning to the tank when it shouldn’t be, this might point to the issue.

-

Water Is Returning to the Tank: If you’ve determined that water is returning to the tank, the pressure controls might be the problem. Let’s break down the potential culprits:

-

Unloader Valve: This valve should direct water to the nozzle until the set pressure is reached. After that, it dumps any excess back to the tank. If this isn’t happening, your unloader might be on the fritz.

-

Flow Control Valve (3-Way Valve): The flow control should bypass water completely when the handle is on and not at all when the handle is off. If this isn’t the case, it’s time to replace the valve.

-

Pulse Valve: This valve controls how much water bypasses the system. When it’s closed, there should be no bypass. If it’s open, you’ll see more bypass—and you’ll feel hose vibration. If your pulse valve isn’t behaving, it could be causing your low pressure issues.

-

-

Water Isn’t Returning to the Tank: If water isn’t making its way back to the tank, the problem is likely with the pump’s GPM. Here’s what to check next:

-

Water Filter and Engine RPM: Double-check that your water Filter is clear and your engine RPM is at the right level. You might need a tachometer for this—most units should run at about 3550 RPM under load.

-

Suction Side Leaks: Loose fittings on the suction side can allow air into the system, causing rough operation and low pressure. Make sure everything is tight and leak-free.

-

Discharge Side Leaks: Any leaks on the high-pressure side will result in a drop in pressure. Fix these leaks before looking for more complex issues.

-

Advanced Troubleshooting: When It’s Time to Get Your Hands Dirty

So, you’ve done the basics, and your jetter is still underperforming. Time to roll up your sleeves and dive into more advanced troubleshooting:

Relief Valve Settings:

Your relief valve (or unloader valve) controls the pressure by redirecting water flow when you’re not using the jetter. If it’s not set correctly, you’ll lose pressure. Adjusting this valve can be tricky, so refer to your manual or give us a call for advice.

Check the Belt:

If your machine is fitted with a belt, if it becomes loose or worn it can cause the pump to operate below its optimal speed, leading to lower pressure. Inspect the belt for wear and ensure it’s properly tensioned.

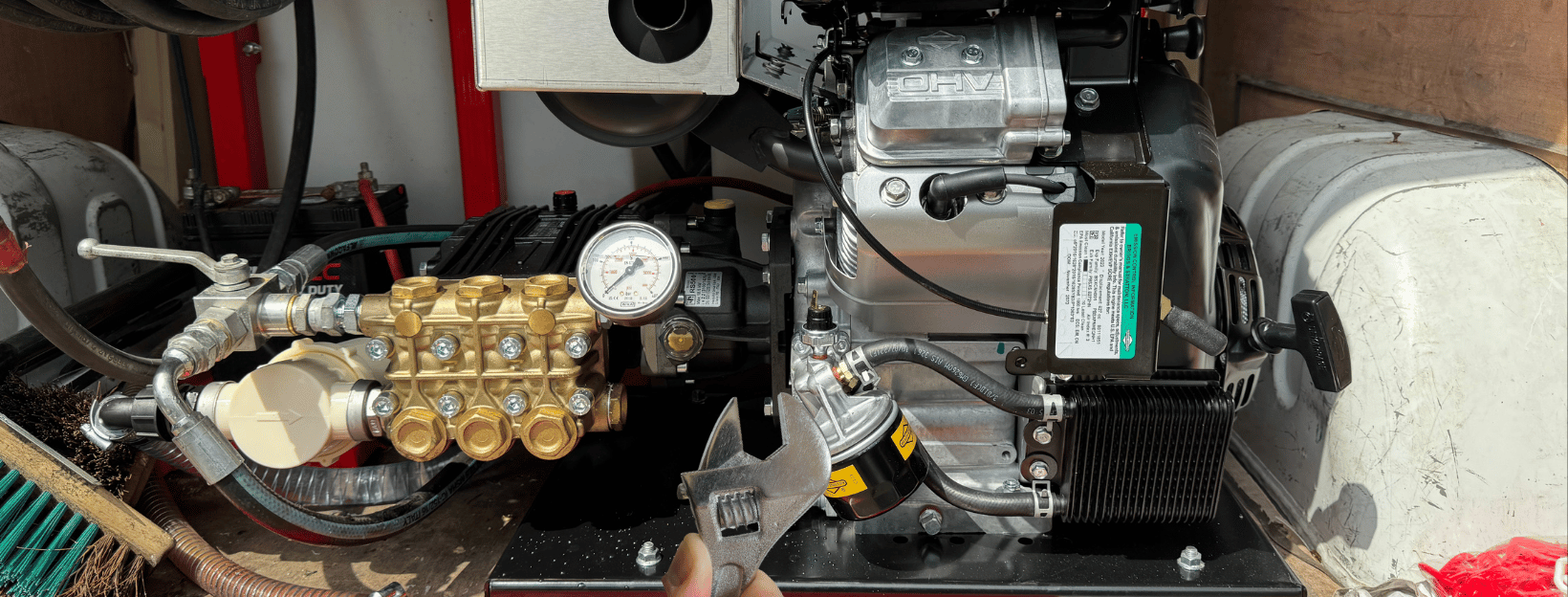

Examine the Pump:

At this stage, the pump itself could be the issue. Check for unusual noises, vibrations, or leaks. If you suspect a pump problem, it might be time to call in a professional for a thorough inspection.

If you’ve gone through all the above steps and still can’t get your jetter back to full pressure, it’s time to dive into the pump itself:

-

Pulsation Issues: If your jetter is pulsating or the flow isn’t smooth, you might have a cylinder that’s not working properly. This usually leads to about half your normal pressure.

-

Check the Valves: Disassemble the check valves under the six stainless steel plugs on the pump head. Look for debris, breakage, or damage to the O-rings that seal the valve seats. If these components are in good shape, you can reuse them. While you’re at it, turn over the engine and make sure all three plungers are moving. If one isn’t, you might have a bigger issue on your hands, like a crankcase or gearbox failure. Only operate this action if you are confident in knowing what you are doing. If you are not you could cause serious damage to either your self or machine. If in doubt just speak to the team and we can guide you through it.

-

- Pressure Loss Without Pulsation: If you’re losing pressure but not experiencing significant vibration, the issue might be with the pump seals. Replacing these can often fix the problem. Again this should be verified and guided by one of our engineers you don't want to risk blowing your pump if parts are incorrectly replaced.